The Gyralite in place, but before the proper Pyle headlight bezel had been found.

1291 St. Nicholas Mountain

1292 Going-to-the-Sun Mountain

Glass retainer bracket

Glass retainer bracket

3D printed replacement

From parts manual

Parts list

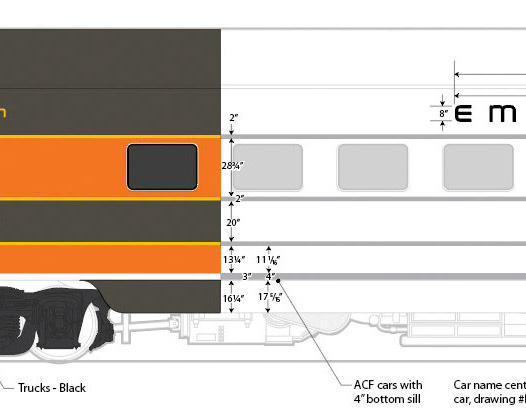

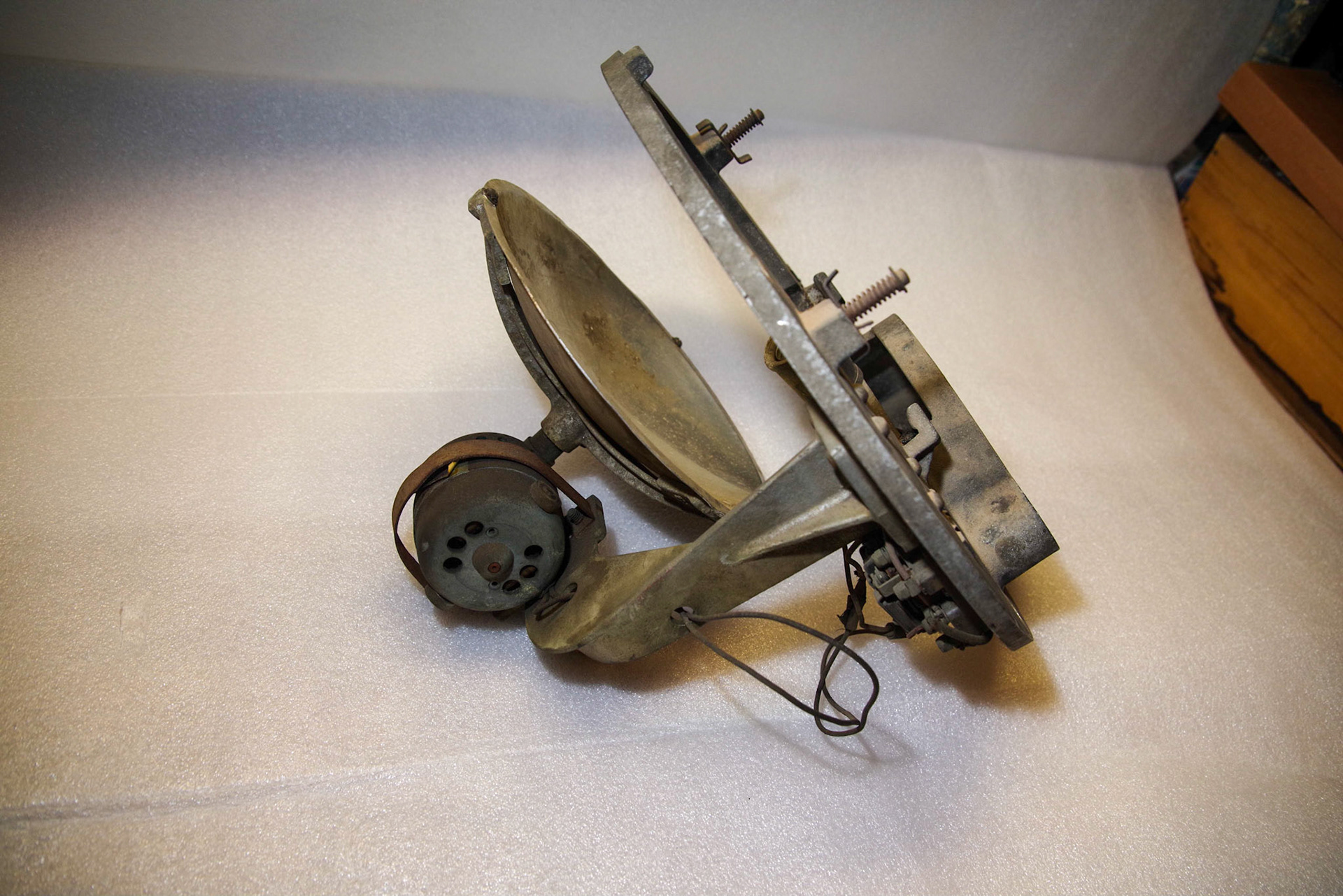

The ACF drawing shows the general arrangement of Gyralite components

Ben liberating the Gyralite mechanism from 1292

The gyralite front had been painted black

The red lens and headlight retainer ring were missing

Luckily the motor worked fine

Jeff liberates the aluminum housing

St. Nick's lens had been replaced with a piece of plastic

Door and housing together

Cleaning up

Retaining clamp

New lens installed

Brush housing

Motor brush

Motor and gear assembly

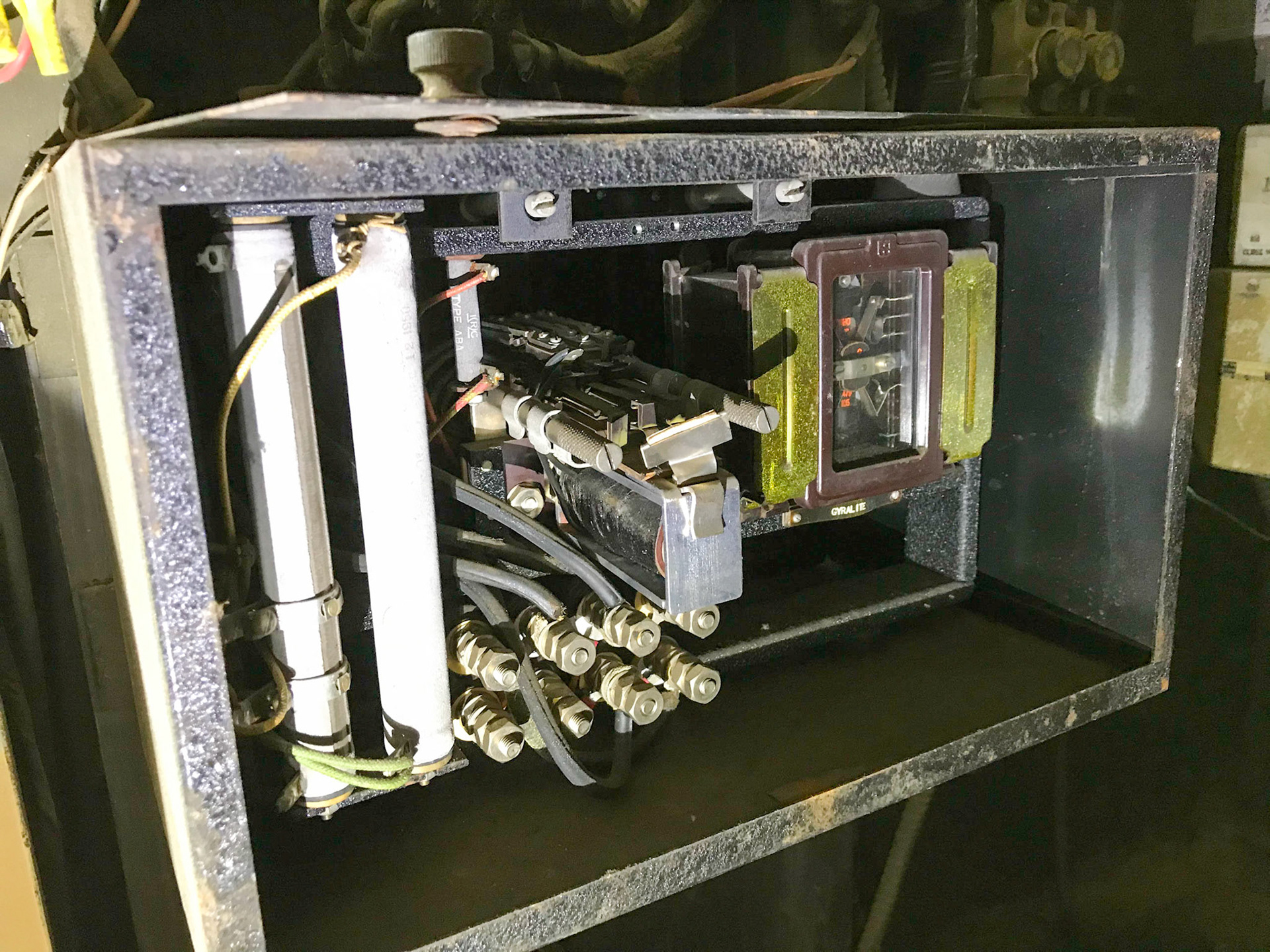

Electrical components

Reflector dish

Headlight on

Red light on

Assembled unit in housing

Headlight clearance is tight!

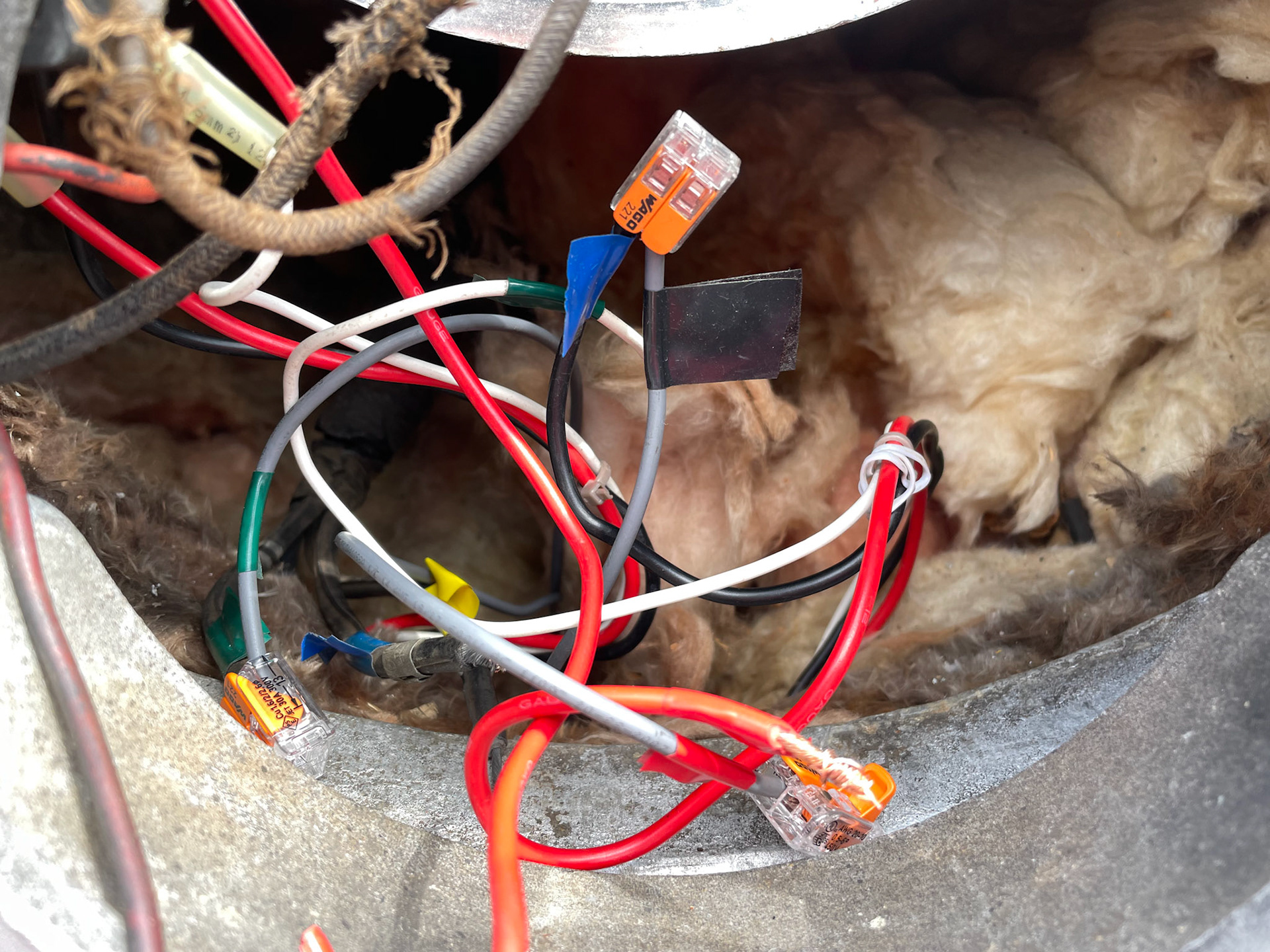

The functions of the Gyralite are controlled by a relay that ensures that the headlight and rotating red beacon functions operate independently, and allow for activation from any of the three control switches throughout the car.

Ready for reinstallation

Three 10# and one 14# wires for operation

Wago terminals used

Ready to go...

ACF blueprint for ceiling conduit layout

My simplified version of the ACF blueprint

Brakeman's control switches in the vestibule

Inside the switch panel

Emergency switch is inside a weatherproof enclosure with plunger actuator

Emergency activation switch outside at the rear of the car

Weatherproof plunger

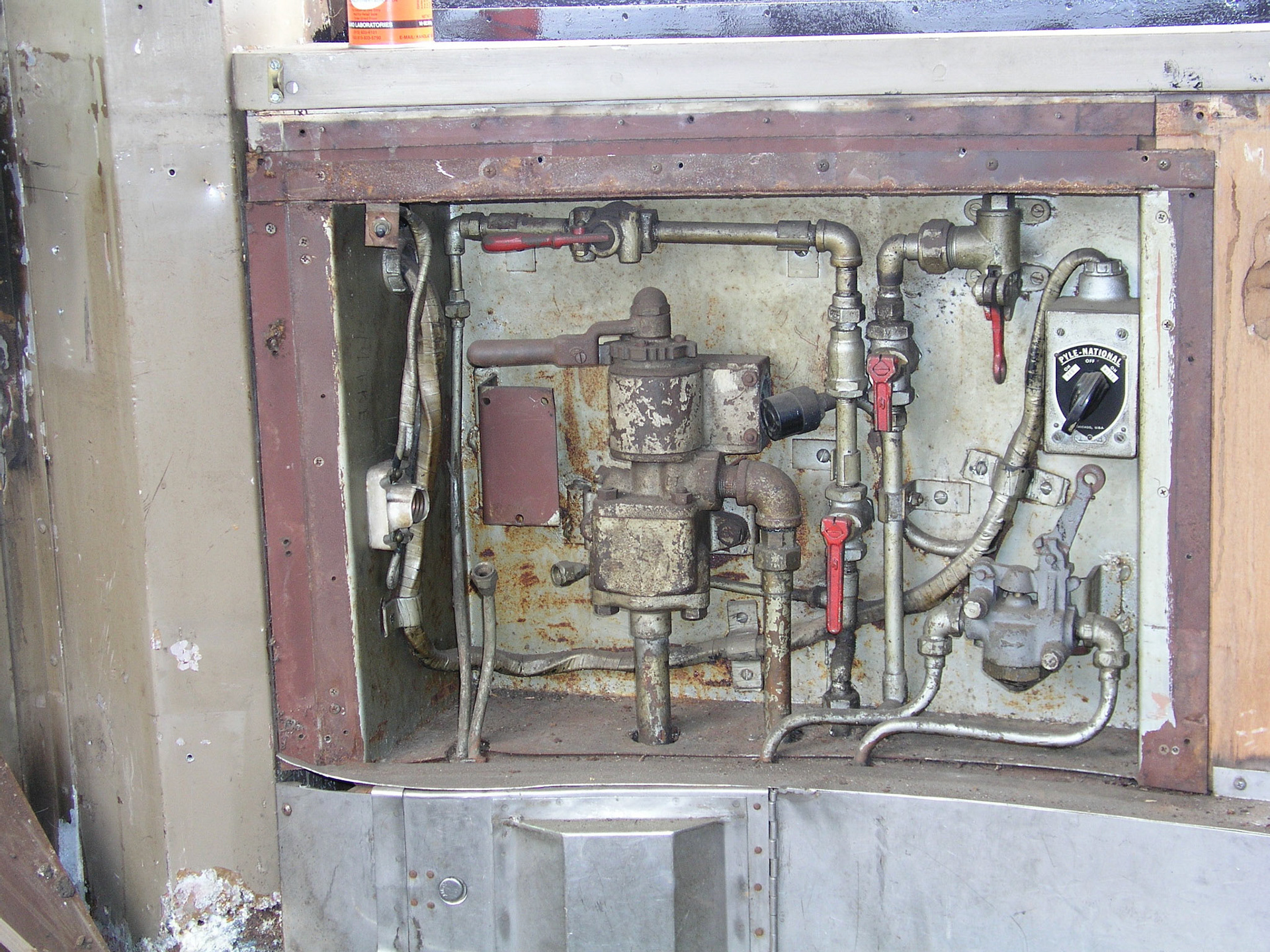

Apparatus in the main electrical cabinet controlled the Gyralite's speed and brake sensors

Main fuses for the Gyralite in the main electrical cabinet

Conductor's cabinet

Gyralite selector switch is at upper right

My simplified diagram of the wiring and components for the Gyralite operations

The replacement headlight retainer ring and hinge were taken from this broken twin sealed beam Pyle Gyralite model.

Ben loves his Gyralite!