Lake Shore Rwy. Museum in the NYC depot at Nort east, Pa.

Signal tower and Little Joe

CSS&SB Little Joe 802

The levers at left are the regenerative braking and throttle controls. Air brake stand in the middle.

View west

View east from the other cab

Fireman's side

Engineer's side

Fireman's side

Seat and controls

Throttle and regenerative brake stand

Cab view

Lots of room inside the nose.

Headlight features two potentiometer coils to adjust voltage

Number board

Air brake reservoir above

Traction motor blower and ir compressor

Traction motor blower

From inside looking towards the cab

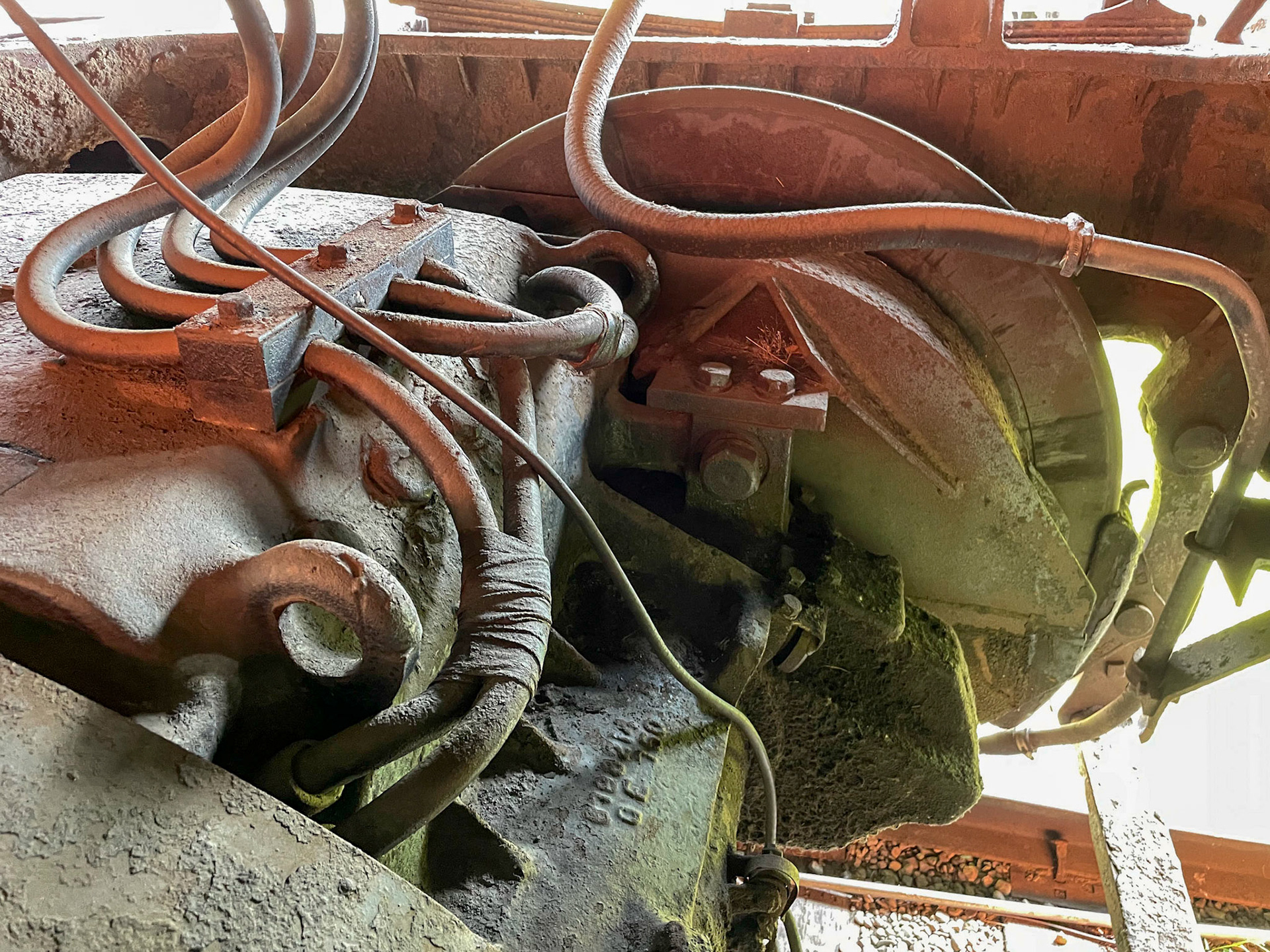

Control apparatus

Traction motor blower motor

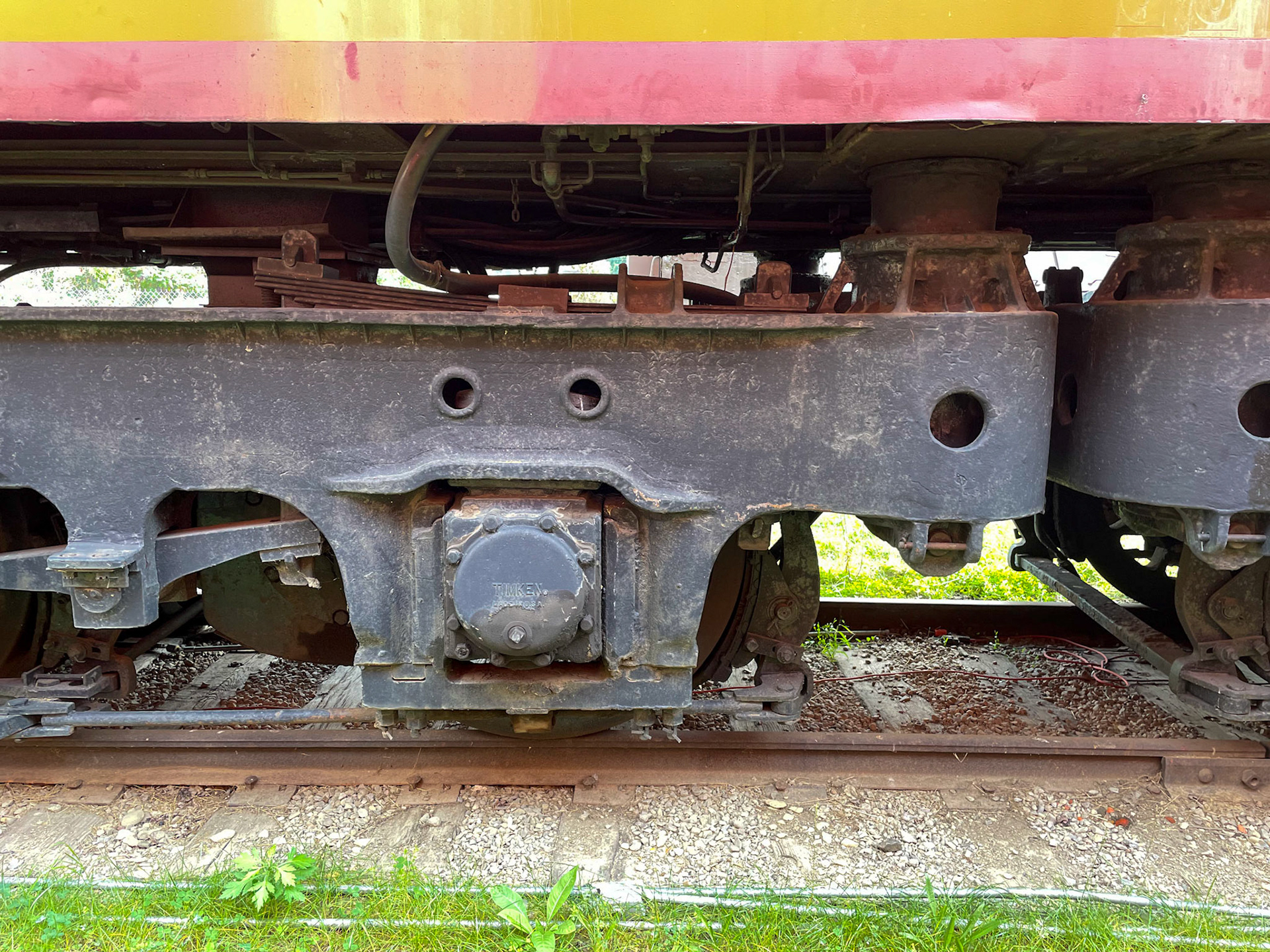

Note that these units were built with spoked wheels.

Load pads carried the weight in the middle

Load pads slid as the trucks turned

Traction motor blower feed

Traction motor

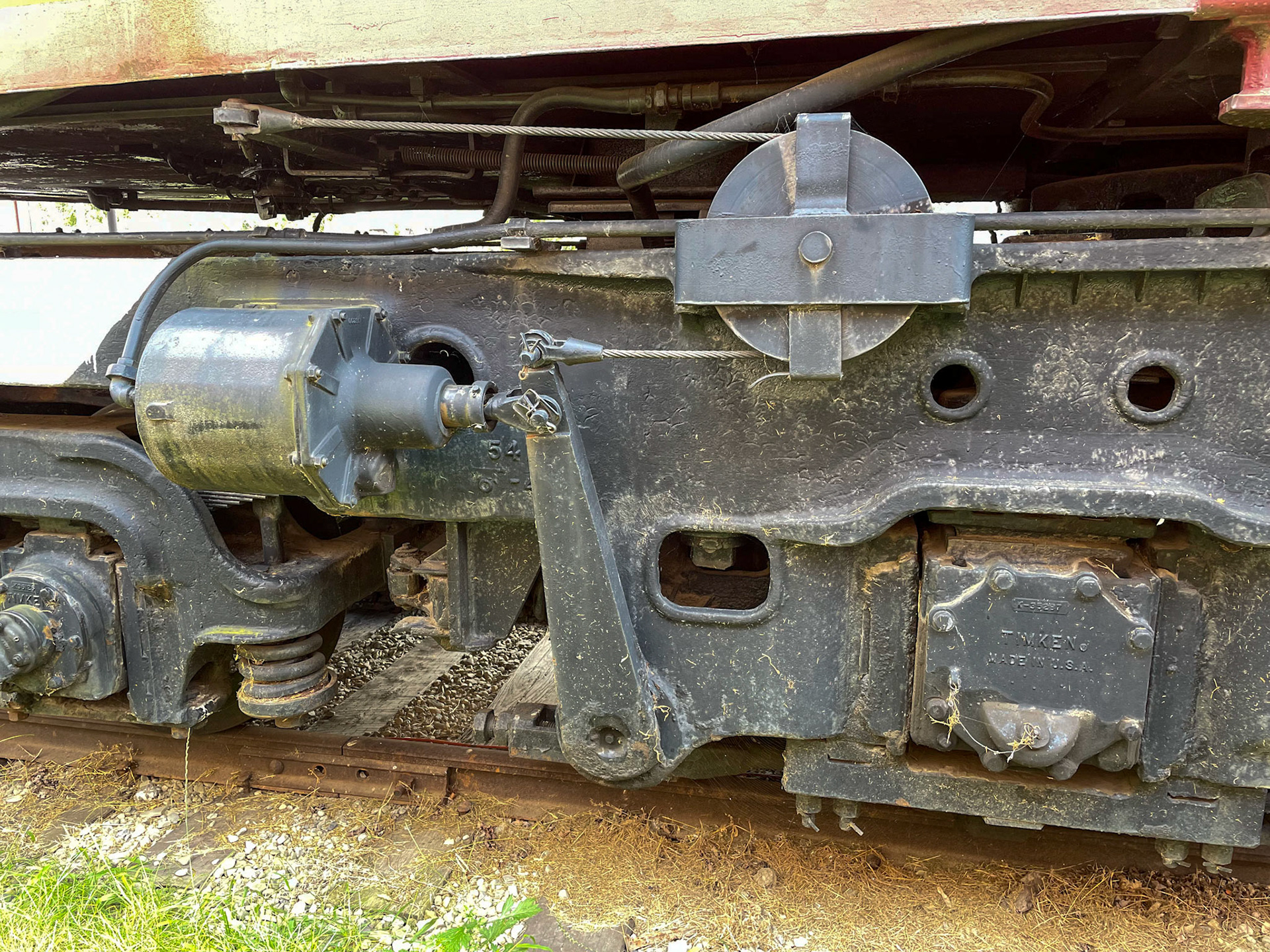

Pin linking the frames of the fore and aft main truck frames

Load pads

Traction motor and spoked wheel

Manual brake linkage pulley tied to brake cylinder and lever

Unpowered lead and trailing trucks

Lead truck under the pilot

Inside the main truck frame casting

Linkage between the main truck frame and pilot truck

G.E. - we bring good things to life....